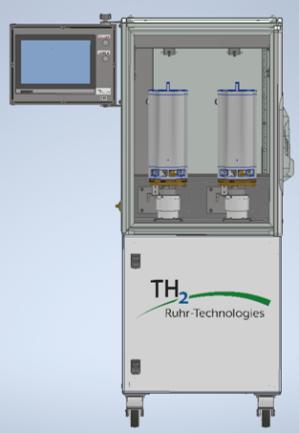

Data Sheet CPF2-S

The TH2 powder feeder CPF2-S stands for:

Precision, speed, long-term stability, repeatability, documentation, simple operation

The CPF2-S is a gravimetric high-end powder feeder. Two independent, closed-loop

control circuits for powder and carrier gas guarantee its precision and excellent

conveying stability. It is now also equipped for conveying submicron powders.

Finest coatings of the highest quality

The CPF2-S of TH2-Ruhr is a very precise, fast, long-term stable and robust powder feeder. Proven and qualified in the aerospace industry, it is particularly suitable

for other industrial sectors where short spraying cycles, high process stability, repeatability and traceability of the process are important. The CPF2-S is optimised

both for very short control times and for high-precision control in continuous operation. Control is achieved via one closed thermal gas mass flow control loop,

independent of the powder flow, and one mechanical gravimetric powder mass flow control loop.

The CPF2-S is suitable for all thermal spray processes such as plasma spraying, HVOF, HVAF, powder flame spraying, laser powder welding and other related processes.

Due to the modular hopper system, <<3μm submicron powders, <10μm superfine powders, <25μm fine and powder particle sizes in the range 5 -125μm can be conveyed. If you want HVOF blasting, the CPF2-S can convey blasting powders up to a grain size of <700μm (EKF 60).

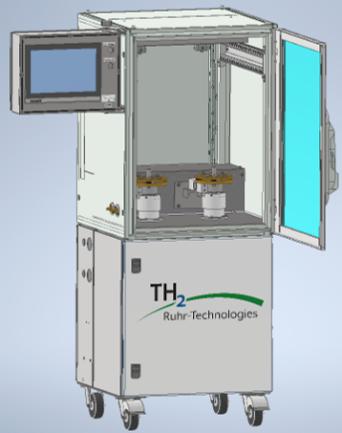

Positioning and connection of the containers in the housing are very simple. It is conceivable to use powder-specific containers for quick replacement when changing the powder. A separate work screen is available for storing the powder quantity in the container used, for easier operation.

The CPF2-S is equipped with two independent, switchable powder lines that can be used simultaneously.

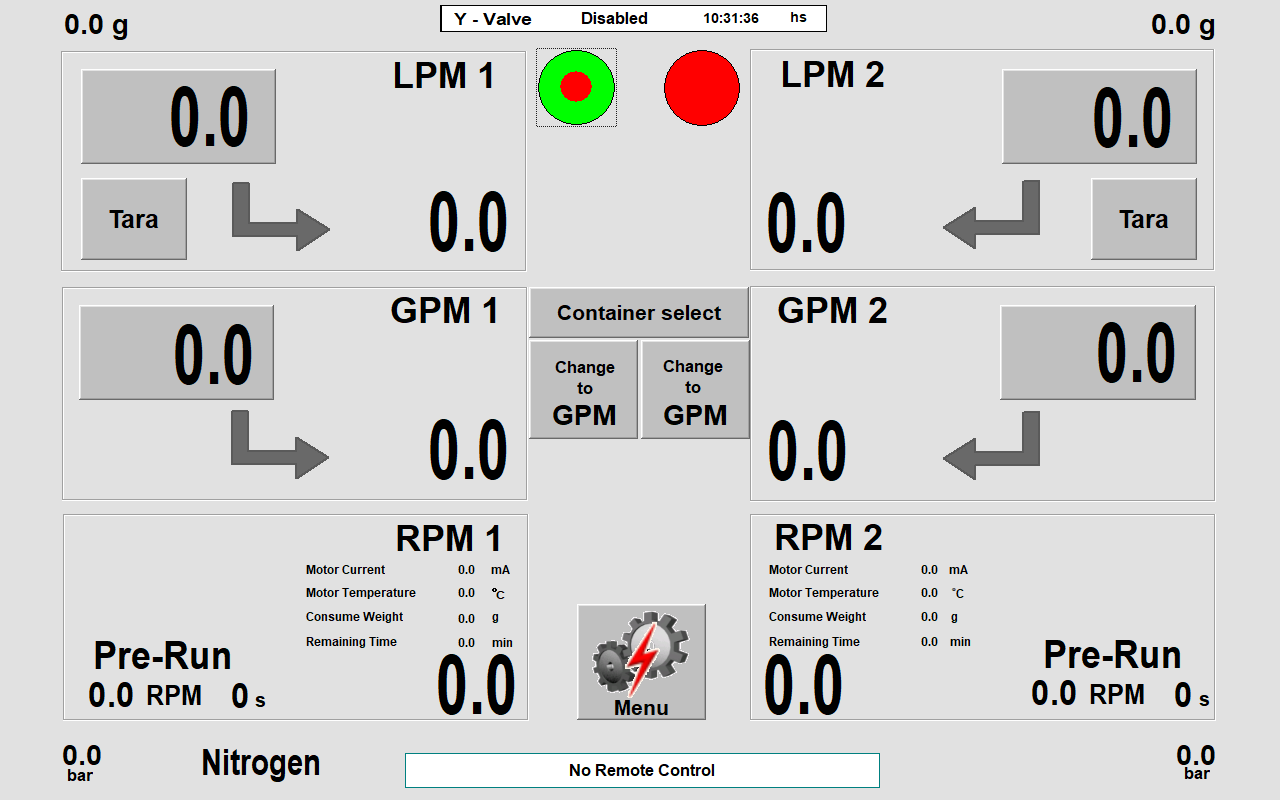

Operation is via the powder conveyor's own HMI or, in the case of integration, via the HMI of the metal spraying system. The process documentation is stored, traceable and easily readable over an operating period of 30 days.

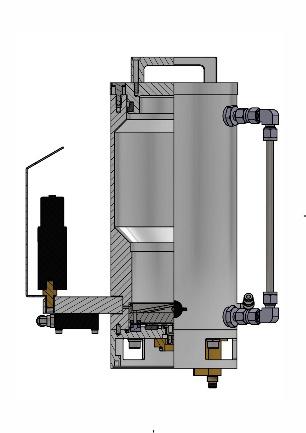

A special highlight is the new powder container for submicron powders <<3μm. It enables functional, dry conveying of submicron powders as an alternative to suspension spraying. This expansion of the usable powder spectrum into the submicron powder range is a milestone in thermal spray technology.

- Two switchable or simultaneously usable powder lines

- Powder hopper for submicron powders <<3μm

- Powder hopper for micron powders, standard sizes 3.5l and 5l

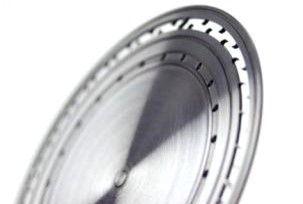

- Conveying discs S, L, H and XH for conveying powders for different quantities and applications, conveying quantities 0.5-10g to 20-800g

- Two closed-loop control circuits for carrier gas mass flow control and gravimetric mass flow control based on a scale feed disc design

- Carrier gas control using the latest generation of highly stable thermal gas mass flow controllers.

- Accuracy of powder feed in continuous operation with max. deviation < +/- 2%* results in high stability and process reliability. (*150g/min with gas atomised powderNiCr20)

- State-of-the-art PLC and hardware

- Real-time monitoring, logging, storage and export of process parameters

- Storage of recipes and presettings of the conveyor disc speed enables fast start-up, thus saving time, expensive materials and media

- Stand-alone operation and remote control. Can be integrated into existing systems and parameter-monitored processes via Ethernet interface or other fieldbus systems

- HMI with industrial PC and large, separate 12"(304mm) touch screen, optionally removable

- Large, clear display of process parameters, warning in case of deviation from defined limit values

- Container and powder gas heating for processing submicron and superfine powders at high humidity levels

- Pressure range standard for 10bar and optional 20 bar.

- Easy container and powder change

- Design: gas-current separation

Clear operation

The CPF2-S is smart and combines intelligent design with clarity of operation and information.

Videos:

Following videos show the very short adjustment time to the set flow rate setpoint (GPM).

Parameters: Set point flow rate 20 g/min,

NiCr base powder, -53 + 22μm, disc S.

Parameters: Setpoint flow rate 150 g/min,

NiCr base powder, -53 + 22μm.

Parameters: Setpoint flow rate 50 g/min,

NiCr base powder, -53 + 22μm, disc S